Choosing the right refrigerated truck isn’t just a technical decision — it’s about protecting your product and your business reputation. Get it wrong, and an entire shipment could go to waste.

So, how do you know if you need a chilled truck, a frozen truck, or just a simple puff container? Let’s make it simple.

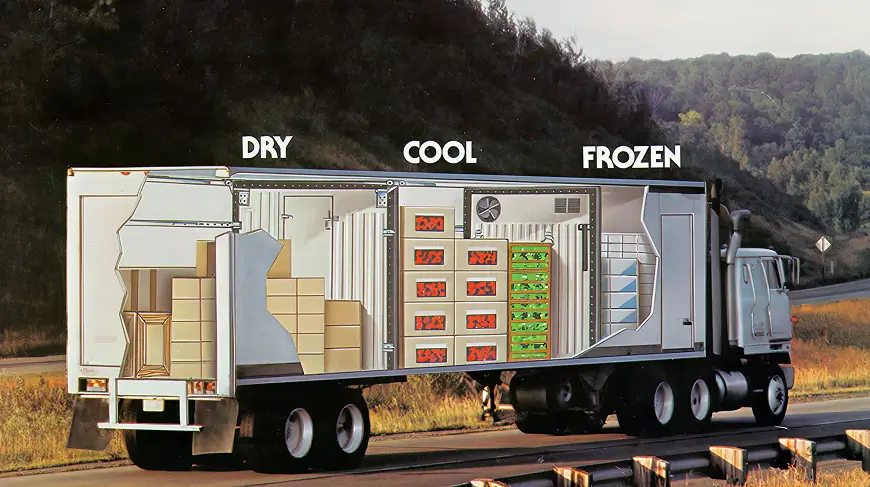

Imagine Your Fridge at Home…

Think about the refrigerator in your house. The bottom shelves are cool — where you keep vegetables, chocolates, or cakes. The freezer on top? That’s where the ice cream and frozen peas go.

Now, imagine that fridge being laid on its back, stretched into a truck-size container. That’s basically how a reefer truck works — chilled and frozen sections, but on wheels.

Of course, in reality, things are a bit more complicated than your home fridge — but this picture helps you get the idea.

Why Temperature Range is Everything

Whether it’s humans, animals, or food, everything survives only within a certain temperature range. Too cold? It freezes and dies. Too hot? It burns out.

Food products are no different. Milk, paneer, chocolates, medicines — each has its own “comfort zone.” Step outside that range, and the product spoils or changes form.

So before you book a truck, ask yourself:

👉 At what temperature should my product stay fresh?

The Early Morning Milk Story

Have you ever wondered why milk distribution always happens early in the morning?

It’s not just tradition. Early mornings are naturally cooler, so when milk packets are loaded into a puff container (an insulated truck without an AC unit), the product’s freshness is maintained for 2–3 hours.

If the same thing is done at noon under a hot sun, the milk will spoil in less than half an hour — no matter how good the container is.

This is why timing + the right container matters just as much as the product itself.

Chilled Transport – For Freshness Without Freezing

Chilled trucks maintain 0°C to +15°C — the perfect range for products that need cooling but not deep freezing.

Think of:

- Fruits & vegetables

- Dairy products like cakes, whipped cream, chocolates

- Medicines and some chemical items

If you’re delivering fresh meat or packed ready-to-eat meals, chilled transport keeps them safe without making them rock-hard like frozen food.

Frozen Transport – For Deep Freeze Goods

Frozen trucks hold -10°C to -20°C. These are non-negotiable for products that must stay frozen from warehouse to customer.

Typical examples:

- Ice creams (nobody likes melted goo!)

- Frozen meats and seafood

- Paneer, butter, and heavy dairy blocks

- Frozen packed foods

A simple rule: If your product was stored in a frozen warehouse, it needs a frozen truck for delivery too.

Puff Containers – For Short & Quick Deliveries

Some products don’t even need active cooling — just insulation. Puff containers are cheaper and efficient if the delivery is quick.

Perfect for:

- Milk packets (delivered within 2–3 hours)

- Short-distance dairy distribution

But remember: puff containers are only as good as the timing. Morning = safe. Afternoon = risky.

Which One Should You Choose?

Here’s a quick breakdown:

- Fresh & light products → Cakes, whipped cream, chocolates → Chilled truck

- Heavy & frozen products → Paneer, frozen foods, dairy blocks → Frozen truck

- Quick deliveries → Milk packets → Puff container

Still confused? Here’s the safest tip: if you’re not sure, go for a frozen truck. Frozen trucks can be adjusted down to chilled mode — but chilled trucks cannot handle frozen products. Just keep in mind: frozen trucks cost more to run, so you don’t want to overspend when it’s not needed.

Bottom Line: Don’t Decide Alone

Selecting the right reefer truck is important, but equally important is choosing the right transport partner.

A good refrigerated logistics company won’t just send a truck — they’ll ask:

- What product are you moving?

- What time are you delivering?

- How long is the journey?

Sometimes, even just sending a photo of your product helps them suggest the best truck size and temperature setting.

Because at the end of the day, refrigerated logistics is not just about transport. It’s about keeping your product exactly as fresh as it left your warehouse.